PTFE Hose

PTFE Hose

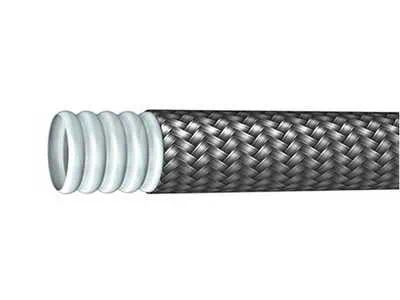

PTFE Hose Manufacturer | Stainless Steel Braided PTFE Hose

Manufacturer-grade PTFE hose with stainless steel braid for extreme temperature and demanding media. The content below guides engineers and buyers to select, validate, and order: performance ranges, testing, documentation, assembly options, and application notes.

Country of Origin: Taiwan OEM Assemblies High Temp • High Pressure • Chemical Media

Product Overview

Operating ranges and core properties

- Temperature: -70°C to +260°C (series dependent).

- Pressure: medium to high with stainless steel braid; impulse-tested by series.

- Media: fuels, oils, coolants, solvents, acids/alkalis compatible with PTFE.

- Properties: low friction, low permeation, non-contaminating bore.

PTFE hose manufacturer, stainless steel braided PTFE hose.

Specification Snapshot

| Construction | Temp Range | Pressure Class | Typical Uses |

|---|---|---|---|

| PTFE smooth bore + stainless steel braid | -70°C to +260°C | Medium–High | Oil/coolant lines, chemical transfer, instrumentation |

| PTFE convoluted + stainless steel braid | -70°C to +260°C | Medium | Tight routing, vibration-prone installations |

| Optional covers (PVC, synthetic fibre) | Per cover spec | Per series | Abrasion protection, color marking, UV shielding |

Select by working pressure, temperature, media compatibility, bend radius, and fitting type. Burst/impulse ratings provided by series.

Testing, Traceability, and Documentation

Test methods

- Pressure, burst, and leak checks under documented procedures.

- Thermal cycling and media compatibility tests for PTFE compounds.

- Dimensional and braid coverage verification.

Traceability

- Batch records from raw PTFE to finished assembly.

- Labels with series, lot, and date codes for audit trails.

Documentation

- COC, test reports, and material statements upon request.

Applications

Use cases for stainless steel braided PTFE hose

- Automotive: oil cooler, turbo, brake/clutch (with appropriate assemblies).

- Industrial: chemical transfer, process gas, steam within temp limits.

- Instrumentation: high-temp sampling, low contamination paths.

Confirm local codes and standards for each application and select fittings accordingly.

Assemblies, Fittings, and OEM Options

End connections

- Banjo, adapters, and connector sets in steel, stainless steel, or aluminum.

- Custom lengths and protective covers for routing and abrasion control.

OEM support

- Engineering review of duty cycle and environment.

- Labeling, private mark, and packaging per request.

How to Specify for a Quote

Checklist

- Working and burst pressure, temperature range.

- Conveyed media and compatibility notes.

- Size (ID/OD), bend radius, routing constraints.

- Fitting type, thread, angle, and assembly length tolerance.

- Documentation needs (COC, test report) and packaging.

Tip: Share duty cycle and vibration details to fine-tune braid and cover choices.