Fitting Accessories

Fitting Accessories

Fitting Accessories | Washers, Retaining Rings, Protectors

Product category overview for fitting accessories supporting hydraulic and pneumatic assemblies. The sections below guide engineers and buyers on types, materials, threads, testing, documentation, kitting, and order prep.

Country of Origin: Taiwan OEM / Private label Hydraulic • Pneumatic • Automotive • Machinery

Fitting Accessories in This Category

Aluminum Washer

- Crush and sealing styles for banjo bolts and adapters.

- Sizes matched to common threads; marked by series for reorder.

- Surface finish options to support corrosion and hygiene needs.

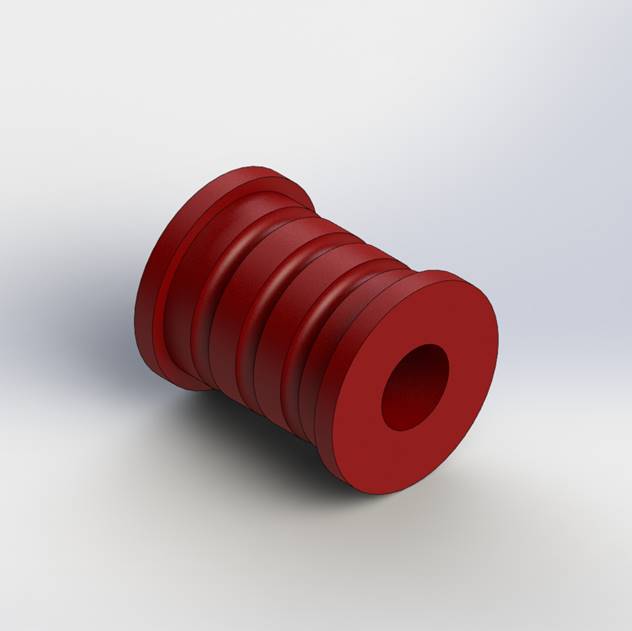

Hose Retaining Ring

- TPU and metal variants to secure sleeves and routing paths.

- Diameter and grip profiles mapped to hose series.

- Color coding for maintenance and identification.

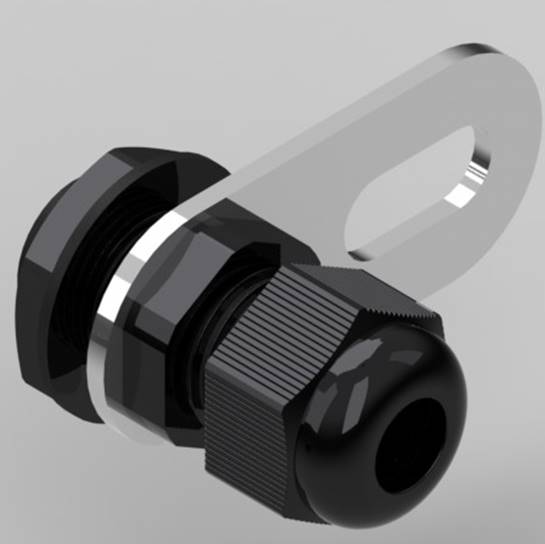

Protectors & Sleeves

- Abrasion and heat protection around contact points and exhaust areas.

- Lengths and wrap types for quick service installs.

- Compatibility notes for rubber, PA, and PTFE assemblies.

Testing, Traceability, and Documentation

Qualification

- Dimensional checks on inner/outer diameters, thickness, and concentricity.

- Pressure and leak checks when paired with specified fittings and hoses.

- Material verification for aluminum, TPU, and steel grades.

Traceability

- Batch records from raw material to finished accessory.

- Series, lot, and date codes for audits and service logs.

Documentation

- COC and test reports available upon request.

- Accessory kitting lists and install notes for field service.

Accessory Comparison Snapshot

| Accessory | Material | Use Case | Main Advantages |

|---|---|---|---|

| Aluminum washer | Aluminum | Banjo bolt sealing, adapter joints | Consistent crush seal, easy identification |

| Hose retaining ring | TPU / Metal | Sleeve fixation, routing aid | Quick install, color-coded options |

| Protector sleeve | Textile / Polymer blends | Abrasion and heat zones | Extended service life, service-friendly wraps |

Select by media, pressure, temperature, fitting type, and service access requirements to match installation goals.

OEM Kitting and Customization

Kits and Labels

- Kits pairing washers, retaining rings, protectors, and connector sets by assembly.

- Labels and markings by series and lot for maintenance tracking.

Design Parameters

- Washer thickness, hardness, and sealing method aligned to torque targets.

- Ring diameter, grip force, and temperature rating matched to hose series.

- Sleeve materials tuned to abrasion zones and heat exposure.

How to Specify for a Quote

Checklist

- Pressure, temperature, and media details.

- Thread standard, sealing type, and torque targets for washers.

- Hose series, diameter, and routing constraints for rings and sleeves.

- Documentation needs (COC, test report) and packaging preferences.

Tip: Share abrasion and heat hotspots to fine‑tune protector materials and ring selections.