Industrial Hose

Industrial Hose

Industrial Hose Manufacturer | PA Hose Category Overview

Product category page for PA hose under an industrial hose manufacturer (factory). Content below helps engineers and buyers compare ranges, testing, documentation, fittings, customization, and ordering steps.

Country of Origin: Taiwan OEM / Private label Pneumatic • Hydraulic • Automotive • Machinery

PA Hose Category: What’s Included

Unbraided PA Hose

- Lightweight tubing with tidy routing and dimensional stability.

- Common for pneumatic control, compressors, and vacuum pumps.

- Color and wall options for identification and bend control.

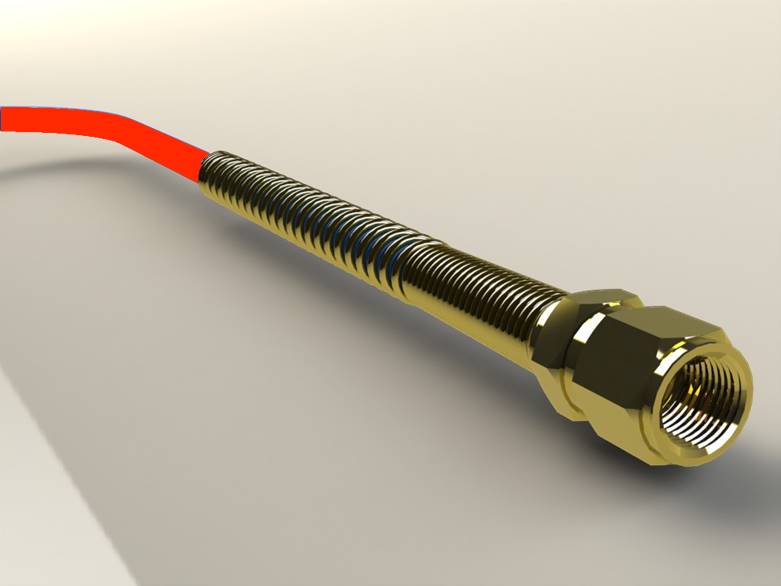

Stainless-Braided PA Hydraulic Hose

- PA inner with stainless braid for medium pressure service.

- Improved abrasion resistance and tighter bend radius options.

- Suitable for fuel and lubricant lines, compact hydraulic circuits.

industrial hose manufacturer, PA hose factory

Testing, Traceability, and Documentation

Qualification

- Pressure, burst, and leak checks on hose and assemblies.

- Impulse testing by series to confirm reinforcement endurance.

- Thermal cycling and media compatibility checks for PA compounds.

Traceability

- Batch records from polymer to finished hose.

- Labels with series, lot, and date codes for audits and service logs.

Documentation

- COC and test reports available upon request.

- Assembly drawings and parts lists for repeat orders.

Comparison Snapshot: PA Hose Types

| Type | Typical Temp Range | Pressure Class | Main Advantages |

|---|---|---|---|

| PA hose (unbraided) | -40°C to +100°C | Low–Medium | Low weight, tidy routing, clean bores |

| PA hydraulic hose (stainless braid) | -40°C to +100°C | Medium | Higher pressure capability, abrasion control |

Ratings vary by series. Select based on working pressure, temperature, media, bend radius, and fitting requirements.

Fittings, Connectors, and Customization

End Connections

- Banjo fittings and bolts (steel, stainless, aluminum) with matched threads.

- Metal adapters and connector sets for pneumatic and hydraulic setups.

Customization

- Lengths, sleeves, and color coding for identification and routing.

- OEM and private label options with documentation packages.

How to Specify for a Quote

Checklist

- Working and burst pressure, temperature range.

- Conveyed media and compatibility notes.

- Size (ID/OD), bend radius, routing constraints.

- Fitting type, thread, angle, assembly length tolerance.

- Documentation needs (COC, test report) and packaging.

Tip: Share vibration and abrasion exposure to fine-tune braid and cover choices.