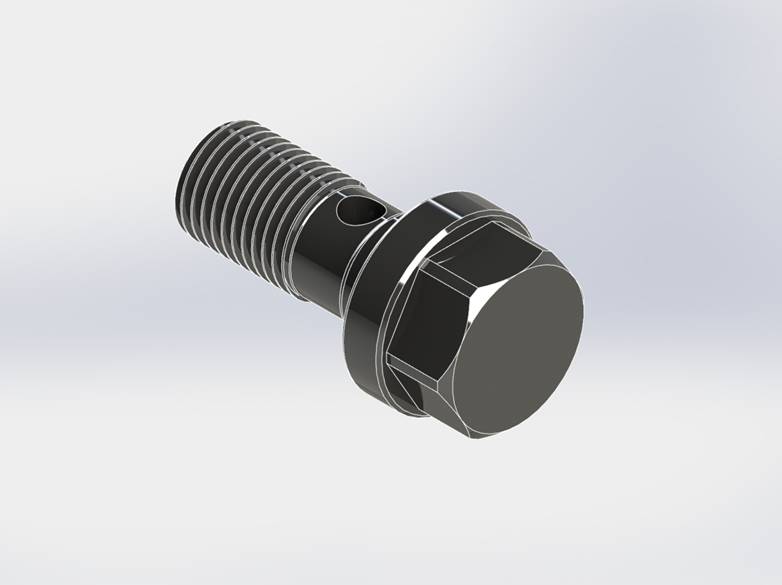

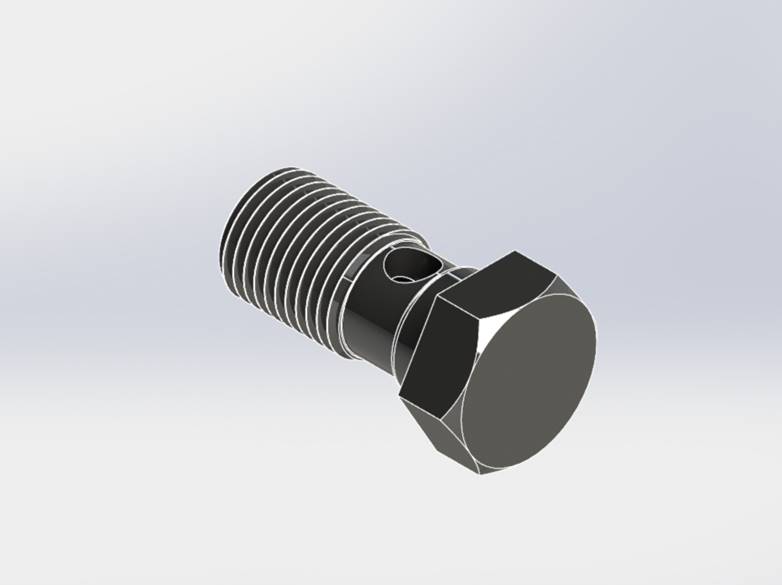

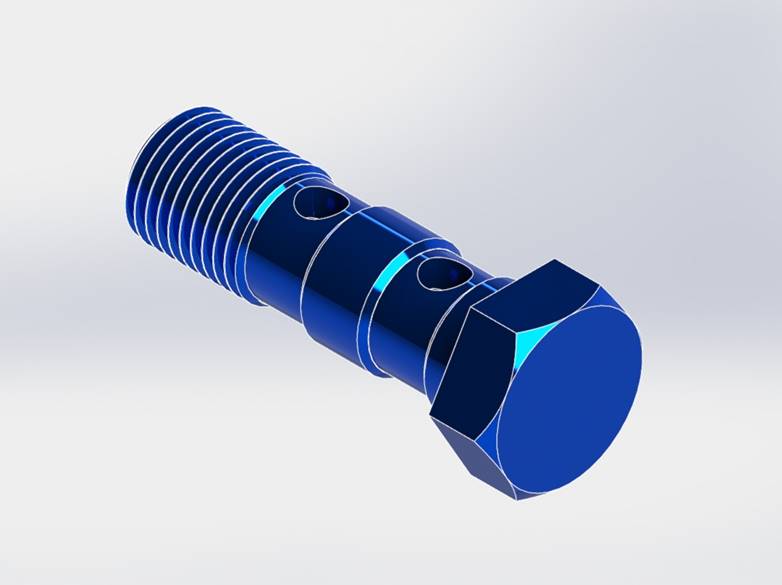

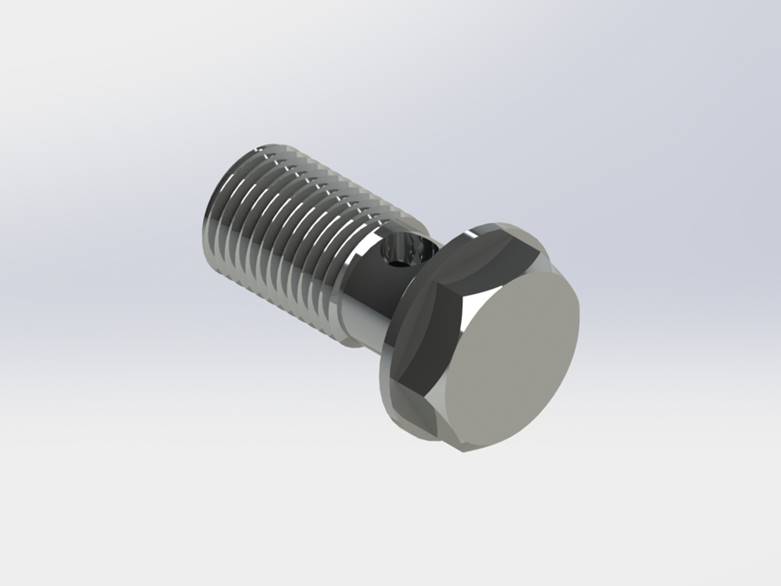

Banjo Bolt

Banjo Bolt

Banjo Bolt Manufacturer & Banjo Bolts Supplier | Category Overview

Category page for banjo bolts used in hydraulic and pneumatic assemblies. Content below helps engineers and buyers compare threads, materials, variants, testing, documentation, kitting, and ordering steps.

Country of Origin: Taiwan OEM / Private label Hydraulic • Pneumatic • Automotive • Machinery

Banjo Bolt Types in This Category

Single Banjo Bolt

- Materials: steel, stainless steel, and aluminum variants.

- Thread standards: metric and imperial; torque windows noted by series.

- Sealing options: washer, cone, or O‑ring matched to fittings.

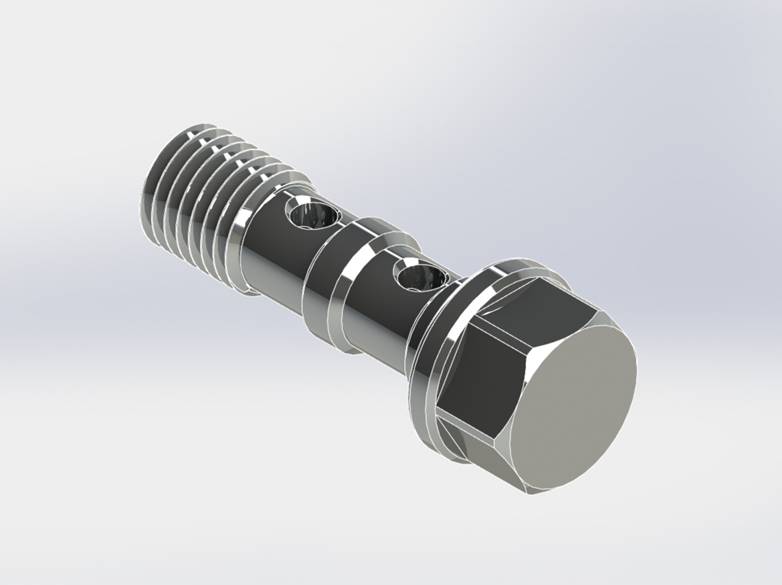

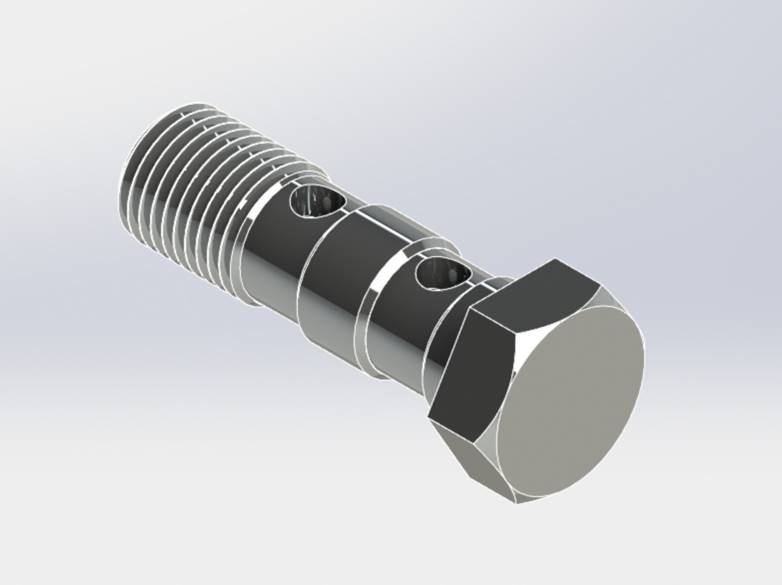

Double Banjo Bolt

- Dual hose interface for compact multi‑line routing.

- Available with bleeder feature for service tasks.

- Angles and lengths mapped to common assemblies.

Service Variants

- Bleeder and high‑profile styles for maintenance access.

- Surface treatments aligned to corrosion and wear requirements.

- Series IDs and markings to simplify reorder.

banjo bolt manufacturer, banjo bolts supplier.

Testing, Traceability, and Documentation

Qualification

- Dimensional checks on threads, concentricity, and sealing faces.

- Pressure and leak checks when paired with specified hoses and washers.

- Material and surface verification per series spec.

Traceability

- Batch records from raw material through finishing.

- Labels with series, lot, and date codes for audits and maintenance logs.

Documentation

- COC and test reports available upon request.

- Assembly drawings and parts lists for repeat orders.

Banjo Bolt Comparison Snapshot

| Type | Material | Thread/Feature | Main Advantages |

|---|---|---|---|

| Single banjo bolt | Steel / Stainless / Aluminum | Metric / Imperial | Simplified routing, broad thread availability |

| Double banjo bolt | Steel / Stainless / Aluminum | Metric / Imperial; optional bleeder | Compact multi‑line interface, service access |

| Bleeder variant | Steel / Stainless | Bleeder port | Air removal and service convenience |

Select based on media, pressure, temperature, thread standard, sealing method, and service access requirements.

OEM and Kitting

Design Parameters

- Thread class, sealing strategy (crush washer, cone, O‑ring), and torque targets.

- Lengths and head profiles matched to routing around frames and components.

- Surface finishes aligned to corrosion and cleanliness goals.

Kitting & Labeling

- Parts labeling by series and lot for maintenance tracking.

- Kits pairing banjo bolts, banjo fittings, adapters, and washers for specific assemblies.

How to Specify for a Quote

Checklist

- Target pressure, temperature, and media.

- Thread standard and tolerance (metric/imperial), sealing type.

- Material choice (steel, stainless, aluminum) and surface treatment.

- Associated hose series, required angles/lengths, and maintenance access.

- Documentation (COC, test report) and packaging preferences.

Tip: Share torque targets and sealing preferences to finalize thread class and washer/cone selections for OEM builds.